-

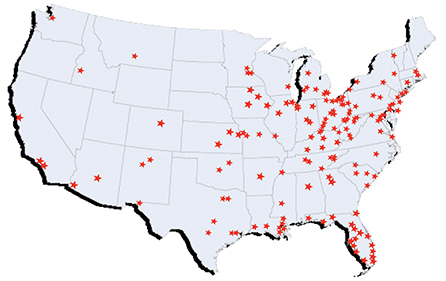

Welcome to Forensic Human Factors, LLC

-

Driver Behavior

The driving environment requires the successful performance of a highly complex series of interconnected tasks, including navigating, speed regulation, observing posted signs and signals, and responding to unpredictable events in a safe and timely manner. Through experience, the cognitive processing demands of driving is greatly reduced, leading many to become complacent or distracted by secondary tasks.

Motor vehicle collions occur when drivers unexpectantly encounter a roadway object or person, or become confused due to defects in the design and maintenance of the roadway. Construction zones often provide challenging environments in which to navigate, and must be designed to provide drivers with adequate and positive guidance.

A disproportionate number of accidents occur at night, due to reduced visibility. We evaluate the ambient, headlight and supplemental lighting in the area of the collision to determine what the driver could or should have seen prior to the collision. The conspicuity of objects, pedestrians and bicyclists is an essential component to a complete visibility analysis.

We have over a decade of experience analyzing driver behavior, including cell phone use and other in-vehicle distractions. Additional human factors issues relate to visibility (line of sight, nighttime), vehicle headlighting and illumination, perception, cognition, reaction time, and reasonableness of the driver's actions.

-

Product Liability

For almost a century, manufacturers have had the burden to provide products that are safe for the intended uses AND foreseeable misuses of their products. When product users are injured through the foreseeable use (or misuse) of a product, we analyze three phases of the product's development: the design, guards and warnings.

Manufacturers have the responsibility to eliminate known hazards, or to take reasonable steps to guard the user from being inadvertently exposed to the hazard. If the hazard cannot be feasibly eliminated or guarded, effective instructions and warnings are necessary to alert and inform the user about the hazard, how to avoid the hazard, and the consequences of not avoiding the hazard.

We can determine the likelihood that the defect existed when it left the manufacturer's hands, if the product was unreasonably altered, and if a defect was the proximate cause of an injury. Product liability often includes human factors analysis of the adequacy of instructions and warnings that accompanied the product.

-

Premises Liability

Property owners must maintain safe premises for patrons and invitees, even foreseeable trespassers. Many of these cases involve slips, trips and falls, in which human factors design principles are often violated, leading to the inability to detect and indentify the hazard in enough time to avoid it. Common examples are sidewalks in disrepair, location and design of retail displays, and visibility and lighting issues.

Other needs for safe premises are locations where railroads are located in close proximity to pedestrian generators and accumulators, such as shopping centers and community parks. Passing locomotives and trains are considered an attractive nuisance, which draws onlookers, especially children. Effective safeguards are essential to protect the public.

-

Slips, Trips, and Falls

These are the most common premise liability cases that benefit from human factors testimony. Our analysis will determine if a reasonably attentive person would have recognized the hazard in enough time to avoid, and when applicable, refute claims that the hazard was open and obvious, based on established scientific principles and testing.

We also analyze the design factors that precipitate falls on stairs and same-level falls. Our engineering services are also able to demonstrate how a dangerous condition could have been reasonably and feasibly eliminated.

-

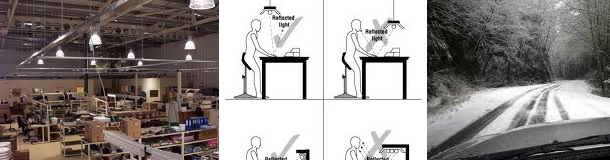

Visibility and Lighting

In order for people to recognize and avoid dangerous conditions, they must be see the hazard. Adequate illumination is critical for people to detect and identify hazards in time to avoid them. We measure the illumination and reflectivity of objects to determine their relative contrast, and the resulting visibility.

-

Workplace Safety

Almost 4,000,000 U.S. workers were injured in 2011. A U.S. worker dies as a result of a workplace injury every 2 hours. While the Workers' Compensation system was designed to provide financial support to those injured at work, many injuries are not the result of the employer's work practices, but rather other entities. Our training and experience in occupational safety and health provides the foundation to investigate defective products, gross negligence or misconduct, or the actions of a third party on the worksite.

-

Machine Guarding

Manufacturers must provide effective guards to separate operators, in time or distance, from a hazard. These guards are often modified or removed, exposing workers to the hazard. There are many feasible solutions available to manufacturers and employers to ensure that their equipment is used properly. Lock-out-tag-out (LOTO) is a preferred method to reduce the inadvertent release of energy. Adjustable guards often provide reasonble safe and efficient operation. When guards are not originally present, modified, or removed, workers may be unknowingly exposed to an unreasonably dangerous condition.